Precision molded parts

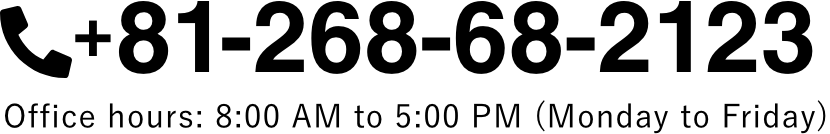

Precision molded part

Use of both high precision mold and thermoplastic with additives such as glass fiber, mineral, carbon fiber for better management of shrinkage rate and thermal stress (expand , shrink) enables large volume production of high precision complex structure molded parts. Our recent application was insert molding that involves insertion of metal part at movable portion of molded product, thus achieving higher precision and durability.

| Material | PPS+MD+GF, PES+GF, PBT+GF, PC+GF, PA+GF and more |

|---|---|

| Insert | Shaft, bearing, threaded insert, etc. |

| Dimension | Available for molding machine size up to 50t to 300t class |

Exterior parts

Exterior parts

Product type includes but not limited to automotive exterior components and electrical and mechanical goods.

Molding with various type of secondary processing (fabrication) including mirror polish and texturing available.

| Secondary processes | Paint, print, plate, vapor deposit, laser cut, other secondary processes available upon request. |

|---|---|

| Dimension | In-house molding available for machine size up to 50t to 300t class. Molded parts of 300t class or more can be handled at partner company. |

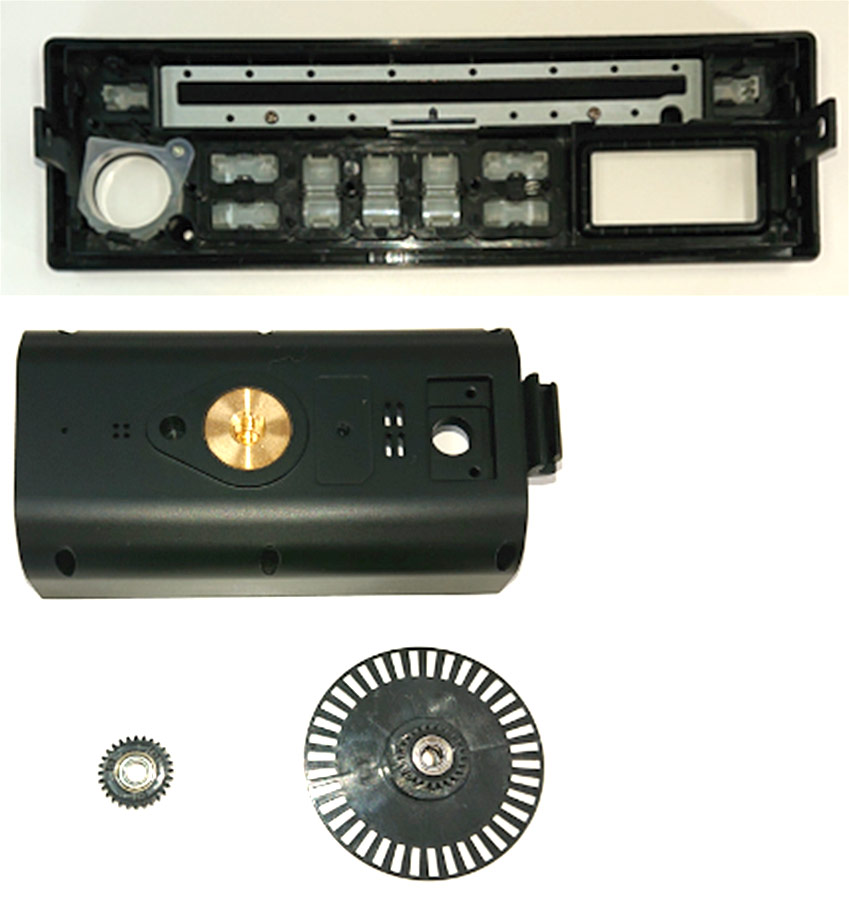

Insert / outsert / assembly processes

Combination of various materials available for insert / outsert molding. Assembly of two or more different molded parts or with other parts also available.

| Insert / outsert | threaded insert, bearing and other various inserts available |

|---|---|

| Assembly | glued, welded (riveted) semi-finished parts |

| Dimension | In-house molding available for machine size up to 50t to 300t class. Molded parts of 300t class or more can be handled at partner company. |

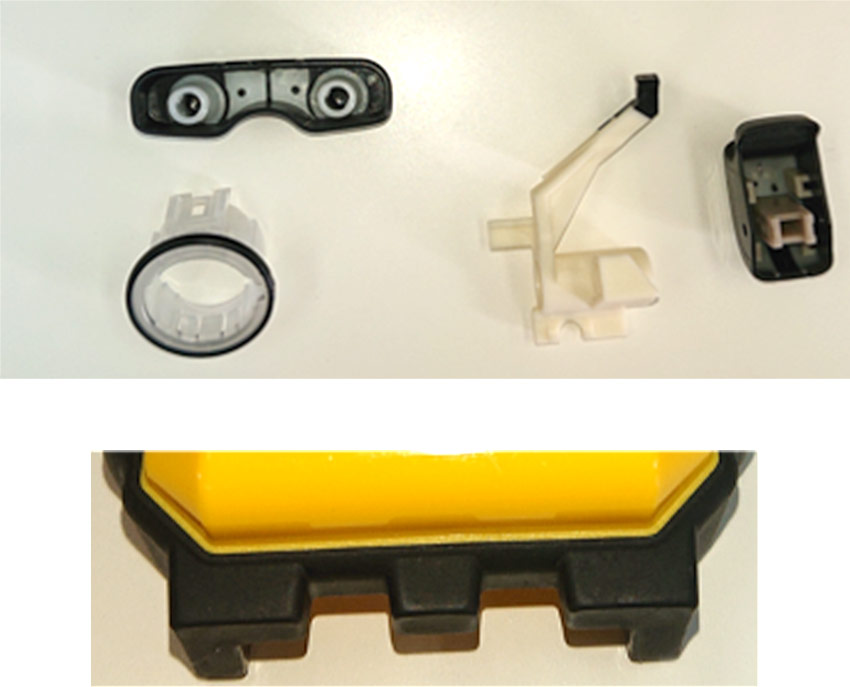

Double material molding / two-color molding

The process allows to mold two different raw materials (example: ABS and elastomer) into one plastic part.

| Available material combinations | contact us for more details |

|---|---|

| Dimension | contact us for more details |

Consulting and Engineering Services

Please contact us if you have problem related to plastic processes (product design, prototyping, new raw material, new molding technology, etc.)

All our team and partners will work together for you to achieve your ideas and designs.